VTM Quality services optimizes production costs with an innovative iiot solution based on mbedge

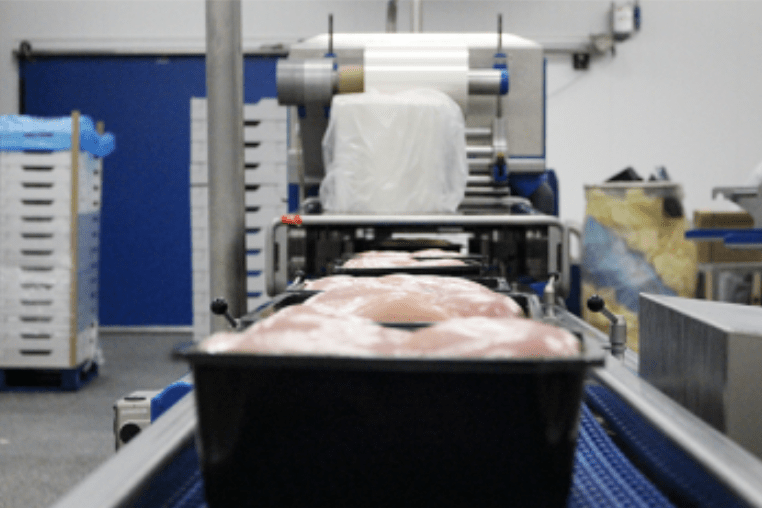

The Dutch company “VTM Quality Services” is active within the food processing industry since 1993 and is specialized in the poultry sector. What VTM QS actually sells to its customers is a complete production service, including the machines, the production lines and the specialized staff to operate and service them.

Operating costs of such food processing production lines highly depend on the predictability of the supply chain and the regularity of its flow. Would there be unexpected delay in deliveries, the lines would just stop. Would there be more deliveries than what production can absorb, preservation of food safety and hygiene may impose to waste some of the stock.

“What is not measured is not managed”

VTM QS understood that, in order to optimize operating costs, they needed to monitor key performance indicators at each production units. Only then would they know precisely where efforts are to be made in the supply chain and how they could try to tune and adjust an ever changing planning of deliveries. So they called in their system integration partner, Schaap Engineering, to design a tailor made solution for them.

Schaap Engineering solution, now called “IOTGATE”, is an integrated modular system that can be quickly adapted to the specific needs of any industry and any type of production. To maximize IT security and OT integration, it is based on MB connect line hardware (mbNET router, with mbEDGE firmware extension) and software (mbCONNECT24 Remote Service Portal).

The mbNET router/edge gateway, installed on the production line, acquires production data from the PLC that coordinates the line operations. The data is then processed on the device to generate the KPI values to monitor. A copy of the KPI values is then pushed securely to a central SQL database, part of the IOTGATE solution, at VTM QS.

Integration with Microsoft

Next to data harvesting, Schaap Engineering solution also takes care of data analysis and presentation. To avoid reinventing the wheel, the technical choice was made to use existing Microsoft tools (PowerBI). This simplified greatly the creation of dashboards for the user interface and the solution could take advantage of the powerful data analysis tools made available in the design environment. It also simplifies the distribution of the final product (the PowerBI “runtime” app’s that VTM QS staff can now download and open on their smartphones) and the control of user access rights. It shortened considerably the development time and made the whole project costs very affordable for such an outstanding result.

Technically, the PowerBI apps generated by Schaap Engineering feed live data, to display on their dashboards, directly from the KPI variables on the mbNET at the production line, while the historical data is sourced from the central SQL database repository at VTM QS.

Local operations staff, at the factory, can now monitor anytime, and from anywhere, the production lines status and performance. They can anticipate future availability or saturation of their lines and take action to try and adjust the supply chain accordingly. As a side benefit, VTM QS product managers have now real production data at their disposal, which they can use for benchmarking and to validate fixes, optimizations and new features.

An open system using common technologies

“One of the remarkable things here”, says Jorik Schaap who contributed to the data presentation and distribution part of the project, “is that, because MB connect line uses common technologies, the products are open and easy to interface with. This helped us a lot for the design of the solution and sped up its implementation. It allows us to keep it modular, so we can adjust it easily to other contexts and use cases.”

Furthermore, remote support & maintenance is a natural part of the solution, using either mbCONNECT24 public remote access service or, as some customers may prefer, using mymbCONNECT24, the private version of it, for even more independence and autonomy. This comes not only as a benefit to Schaap Engineering, for the maintenance of the industrial IoT application on the routers, it is also used by technical support staff to update the routers firmware and keep their security up to date or to service the machines on the production line, as mbNET and mbNET.rokey offer very useful security features and let local staff physically control remote accesses to the production line. The integrated user access control features of (my)mbCONNECT24 make this a very powerful tool.

About Schaap Engineering

Located in Bunschoten-Spakenburg, some 20km North of Utrecht, Dutch company Schaap Engineering BV operates since 1996 and is specialised in Siemens based process engineering, measuring and control technology, programming of machines and visualization of process data. Providing tailor-made solutions, in close cooperation with its customers, typical projects include the automation of power plants and waste processing plants, expanding to development of custom software for industrial machines, such as welding robots and other production lines.

Schaap Engineering’s core business focuses on projects that involve the development of custom-made solutions, where efficiency and consistency are key. It is thus very naturally that the company expanded towards IoT and grew considerable expertise with bringing process data into the cloud and offering their customers the possibility to view real time analysis of production data, even on their smartphones. (see www.iotgate.nl)

With over 25 years’ experience serving diverse industries, Schaap Engineering BV is both a reliable and a knowledgeable partner for creating customized IoT solutions.

For question on Schaap Engineering or the IOTGATE software, please contact the company directly at

Schaap Engineering BV , De Kronkels 5a, 3752 LM, Bunschoten-Spakenburg, The Netherlands.

Website : https://www.schaapengineering.nl/english/